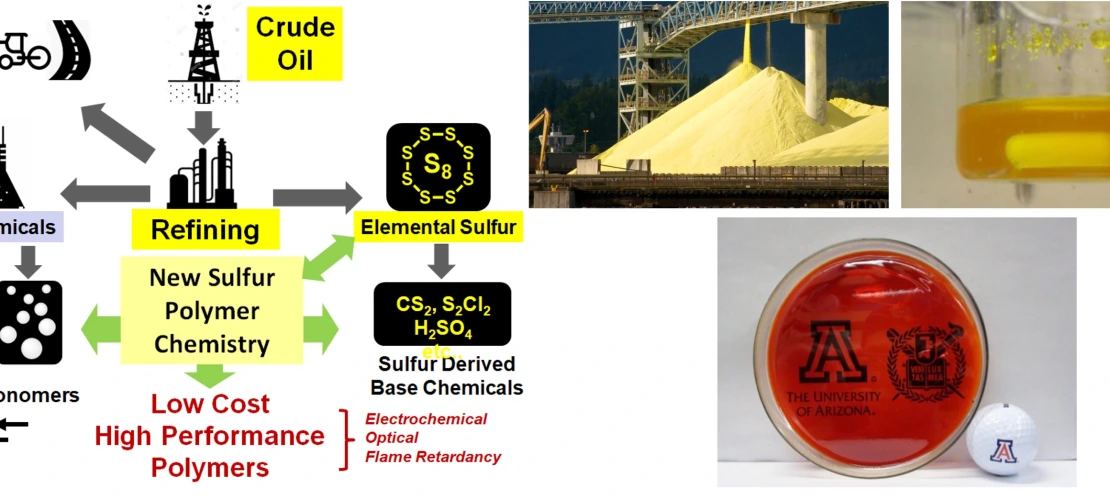

A novel, abundant feedstock for polymers and nanocomposite materials

We have pioneered the utilization of elemental sulfur for novel polymers and nanocomposites. Sulfur is commonly used as a vulcanizing agent in the crosslinking of rubber for tires, however the use of elemental sulfur as the primary monomer, or comonomer for polymeric materials has not been widely explored. Elemental sulfur is currently produced on the level of 70 million tons annually, the majority of which is thru hydrodesulfurization of crude petroleum. Consequently, over 6 million tons of elemental sulfur is generated in excess, which creates exciting opportunities to develop new chemistry and processing to utilize sulfur as a feedstock for polymers. We have invented a new polymerization process, termed, inverse vulcanization, to directly convert elemental sulfur into high sulfur content polymers (Nature Chemistry 2013), which has since launched this technology as a new field in polymer science. Sulfur exhibits a number of useful properties, such as, high charge capacity for Li-insertion electrochemistry and high refractive index. However, the chemical modification of sulfur into useful materials remains a difficult technical challenge. Toward this end, we are developing new polymerization and processing methods for the direct utilization of sulfur to prepare thermosetting polymeric sulfur and nanocomposite materials.

Key publications:

Pyun, et al. Nature Chemistry 2013, 5, 518-524; ACS MacroLett. 2014, 3, 229; Prog. Polym. Sci. 2016, 58, 90; J. Polym. Sci., Part A: Polym. Chem. 2017, 55, 1635; Polym. Chem. 2019, 10, 4078; Angew. Chem. Int. Ed. 2021, 60, 22900; JACS 2022, 144, 5.